What is forward osmosis?

How does forward osmosis work?

What can forward osmosis be used for?

What is the difference between forward osmosis and reverse osmosis?

What is a ‘forward osmosis solution’?

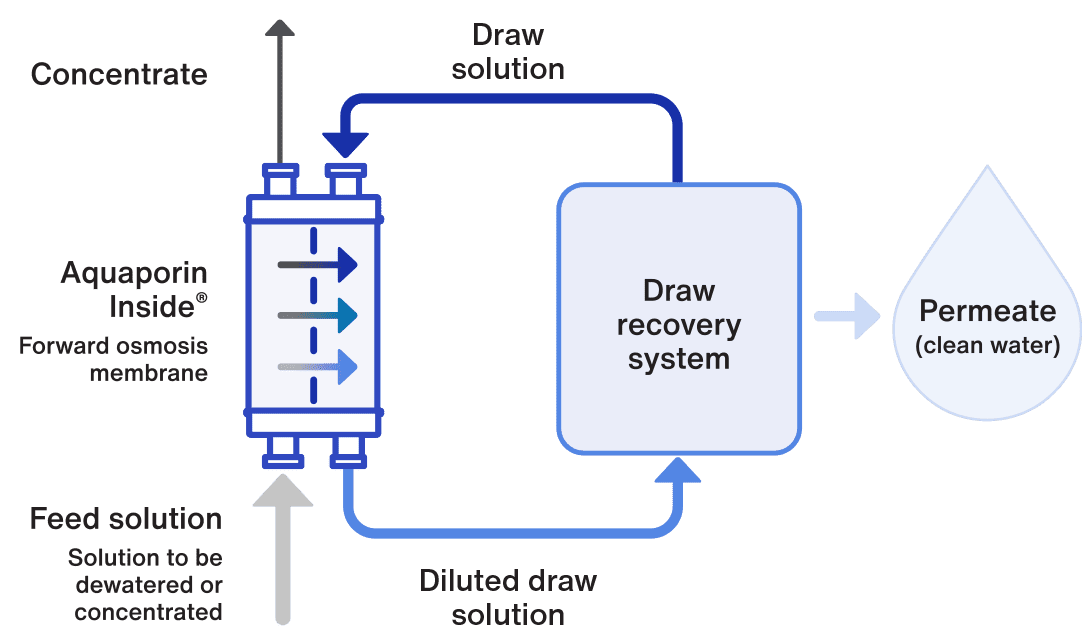

A forward osmosis solution employs a draw recovery system to separate the clean water from the used draw solution. The diluted draw solution is then re-circulated back to forward osmosis step to continuously extract water from feed stream.

In forward osmosis, the water molecules are drawn from the feed solution into the draw solution. In order to produce clean water and recover the draw solution for reuse, the two need to be separated using another type of water treatment system – a draw recovery system. The draw recovery system can be based on either evaporation, membrane-based (typically RO) or thermo-responsive draw solutes.

The main components of a forward osmosis solution are:

The forward osmosis membrane

The forward osmosis membrane allows water to pass but prevents other substances from permeating. The efficiency with which it performs the latter task is known as the rejection rate. A high rejection rate and robustness against fouling, withstanding elevated levels of Chemical Oxygen Demand (COD) and Total Organic Carbon (TOC) – are key qualities of an effective FO membrane. The membrane must also keep reverse flux to a minimum, allowing as little solute from the draw solution as possible to diffuse across the membrane into the feed solution.

The draw solution

The highly saline draw solution creates the osmotic pressure difference which induces water to flow from the feed solution through the membrane. To achieve optimal results, the draw solution must be precisely formulated to match the composition of the effluent. As the water moves through the membrane and the feed solution is concentrated, the draw solution becomes diluted and ultimately ineffective unless it is reconcentrated in a draw recovery system.

The draw recovery system

The role of the draw recovery system is to restore the Total Dissolved Solids (TDS) concentration of the draw solution and extract clean water for reuse. This is usually accomplished through a conventional sea water reverse osmosis system designed to handle TDS up to 60,000 to 70,000 parts per million (ppm). In some cases, novel draw regeneration processes can be employed, handling up to 250,000 ppm TDS. Depending on the setup of the specific site, the clean permeate can be reused for cooling, rinsing and other wet processes. What's more, if the forward osmosis process is designed to sufficiently high standards, it even becomes possible to recycle the water for use in upstream processes, such as mixing dyes in textile production.

How does forward osmosis contribute to zero liquid discharge (ZLD) or minimal liquid discharge (MLD)?

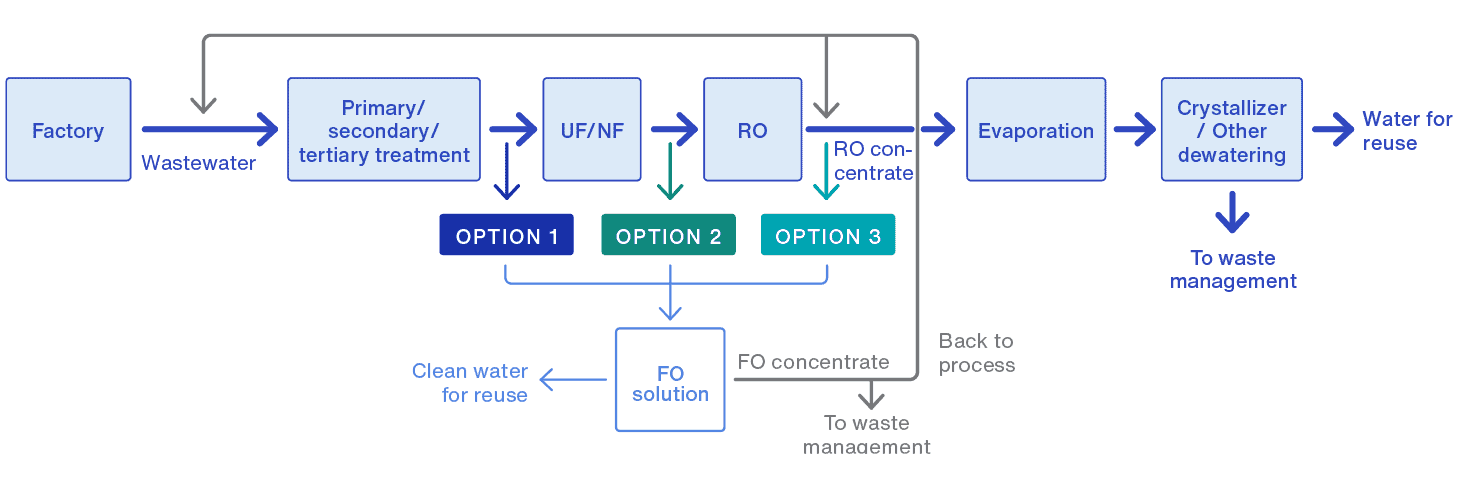

When it comes to ZLD or MLD, FO can be integrated into water treatment systems to improve recovery rates and reduce the energy required for evaporation.

For effluent treatment plants, for example, the ultrafiltration (UF)/nanofiltration (NF) stage can be fully or partly replaced by FO (option 1 and 2). This can simplify the treatment process, increase system robustness when dealing with challenging contaminants and increase the amount of water sent for reuse. FO can also be added after RO (option 3) to further reduce the volume sent to the evaporator and so reduce operating expenses.

These ZLD/MLD systems are becoming more efficient. For instance, Canadian company Forward Water has created a water treatment system that cleans flow back water and produced water from the oil & gas industry with very little energy required for evaporation. This is achieved using a unique draw solution that converts into gas with just a small amount of heat, such as secondary heat from an existing industrial process.

In water-stressed regions like India, where regulation makes the use of ZLD mandatory to address water scarcity and pollution, there is a growing interest in implementing forward osmosis in industrial wastewater treatment processes.

What about reverse flux / reverse transfer?

Like all semipermeable membranes, some solute from the draw solution can diffuse back through the membrane into the feed solution. This is known as reverse flux or reverse transfer and has to be considered when designing a forward osmosis application. Reverse flux is influenced by the choice of draw solution and membrane. The best forward osmosis membranes keep the reverse flux to a minimum in order to minimize draw solute top-up cost in operation.

Do you have more questions that need to be answered?

As a forward osmosis pioneer, we receive many questions about this process method. We have gathered our experts’ answers to an extended list of questions in this e-book, click here to download.