Forward osmosis explained – how does it work and what are the benefits?

Forward osmosis is increasingly used in a range of water treatment applications from food and beverage to industrial wastewater treatment. In this article, we explain what it is and why you should consider using FO for industrial wastewater treatment.

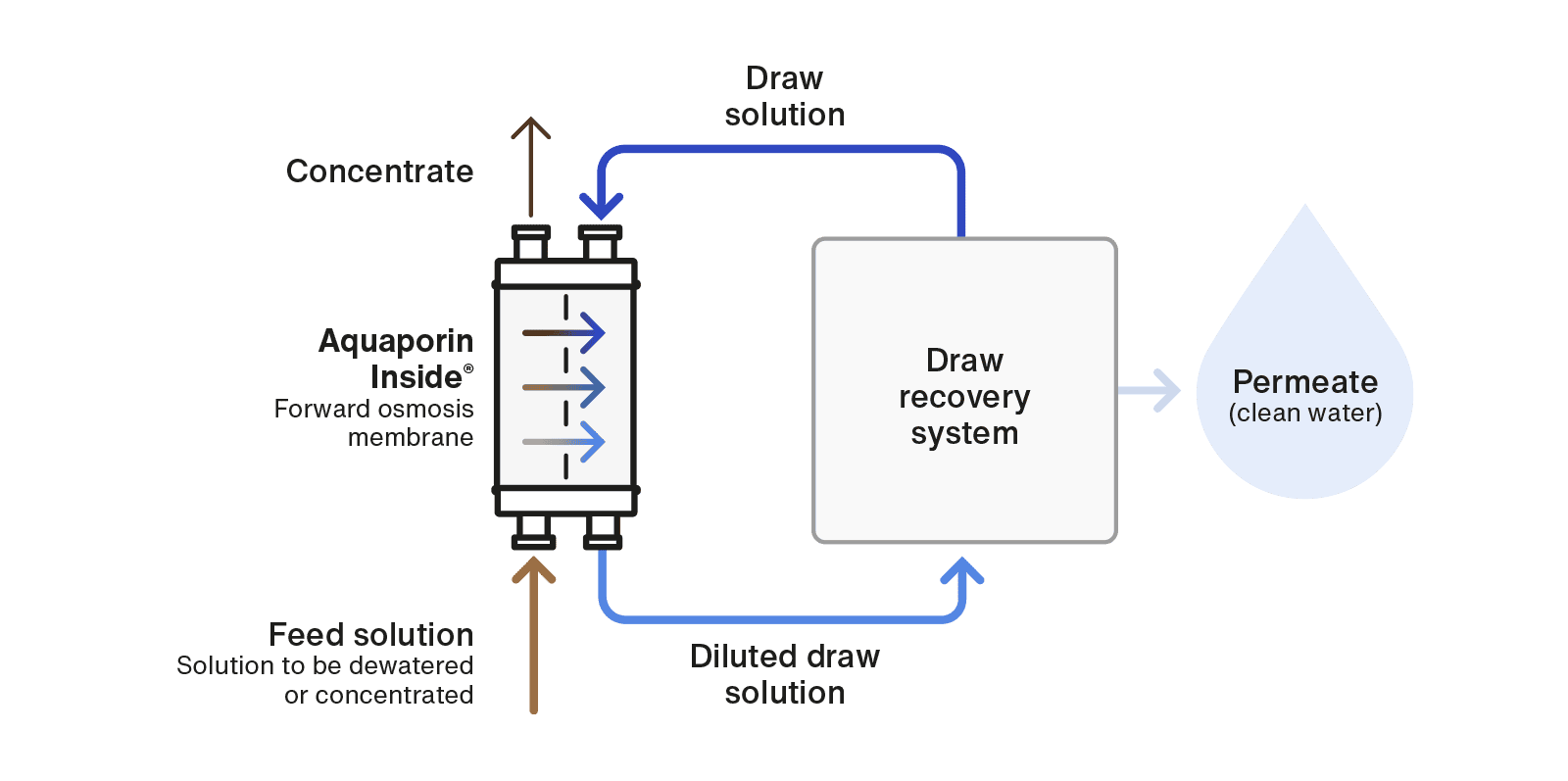

Forward osmosis (FO) is a water separation process which uses a semipermeable membrane and the natural energy of osmotic pressure to separate water from dissolved solutes. In an FO system, a feed solution (such as industrial wastewater effluent) flows on one side of the membrane, while a solution of higher TDS concentration (the draw solution) flows on the other side. The difference in TDS level between the two sides creates an osmotic pressure that transports clean water through the membrane, concentrating the effluent while the membrane retains contaminants in the feed stream.

The main components of an FO system are:

The FO membrane

The purpose of the FO membrane is to allow water to be drawn out of the feed solution while rejecting other substances. A high rejection rate and the ability to withstand harsh factors such as high temperatures, high COD/BOD levels and extreme pH values are key qualities of an FO membrane. The FO membrane must also keep the reverse flux to a minimum, allowing as little solute from the draw solution as possible to diffuse back through the membrane into the feed solution.

The draw solution

The highly saline draw solution creates the osmotic pressure difference which induces water to flow from the feed solution through the membrane. To achieve the optimal results, the draw solution must be precisely formulated to match the composition of the effluent. As the water moves through the membrane and the feed solution is concentrated, the draw solution becomes diluted and loses potency unless it is regenerated in a draw recovery system.

The draw recovery system

The role of the draw recovery system is to restore the TDS concentration of the draw solution and extract clean water for reuse. This is usually accomplished through a reverse osmosis solution designed to handle high TDS levels up to 250,000 ppm. Depending on the setup of the specific site, the clean permeate can be reused for cooling, rinsing and other wet processes. If the FO process is good enough, it is even possible to recycle the water in upstream processes, e.g. mixing it with dyes during textile production.

FO systems are also useful when using them combined with other kinds of treatment systems e.g. as a supplement to reverse osmosis (RO) process for wastewater reclamation as they compensate the deficiencies that the other systems may have. This is also helpful in processes where the recovery of a certain product is essential to minimize costs or to improve efficiency.

What can FO be used for?

FO is generally used for three types of applications:

- Product concentration: Water is extracted from the feed solution, leaving a valuable concentrate (for example, a coffee concentrate).

- Waste concentration: Water is extracted from the feed solution, leaving a concentrated waste product that is easy to dispose of.

- The production of clean water: In both valuable product concentration and waste concentration, water moves from the feed solution into the draw solution. This water can then be recovered to produce clean water.

If you’d like to know more about Aquaporin's Forward Osmosis technology and processes, visit our industrial FO water hub here. If you are interested in learning more about forward osmosis, you can visit our forward osmosis page covering the most frequently asked questions.