There’s science behind flavors

When you take a bite of a fruit, the flavors you experience stem from the fruit’s own natural flavor recipe. Science has made it possible for humans to copy nature’s recipes and control flavor profiles in any desired direction; peely, mature, fresh, you name it. In fact, science has enabled us to understand and replicate even the tiniest building blocks of flavors, and I’ve spent years absorbing this knowledge and indulging myself in the flavor universe. In this blog post, you can explore the world of flavors together with me.

By Karolina Jastrembska, Project Specialist at Aquaporin

How is a flavor defined?

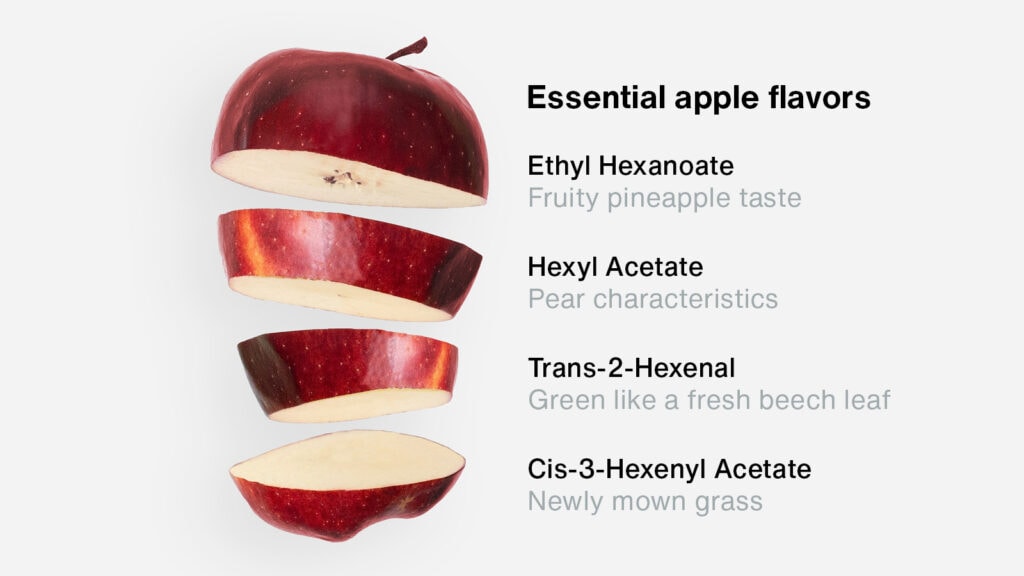

It’s weird, but to define a flavor, we have to start with another sense than the sense of taste, namely the sense of smell. If you hold your nose while tasting a flavor, you’re unable to say what it is. But you are, however, able to describe if it's sour, salty, sweet, bitter, or umami. All flavors appear in our noses first, after which channels transport them into our mouths where we can taste them. Flavors consist of odors from airborne substances, and as we humans have figured out the chemical composition of every single one of these substances, we can isolate them from nature. As an example, the flavor of an apple consists of hundreds of different substances, which all contribute to the individual apple’s flavor profile. Depending on which substances are dominant, the apple will, for instance, taste more or less mature or more like a green apple than a red apple or the other way around. The most essential substances in apple flavor can be seen in the illustration below – as you can see, it borrows characteristics from two other well-known fruits.

Preserving flavors with natural concentration

Food flavoring is being used in various food applications such as dairy, tea, coffee, and stocks. To be able to describe flavors on a technical and scientific level, an industry jargon and a thorough understanding of their composition and categorization are required. My background as a scientist in Chemical Engineering and years-long focus on membrane processes, aromas, and beverages have made me familiar with the steps and precautions we must take at Aquaporin when we help customers develop natural concentrates without using heat or pressure. Instead, by using the power of nature’s own water filtration process, we extract water from raw ingredients to produce concentrates with the original products’ flavors intact.

Zooming in on juices

Many of us have tasted a drink that contains juice from concentrate. It tastes good, but when you think about it, its flavor and taste will probably remind you of jam, or you might feel that something is missing. With Aquaporin’s technology, we can avoid that. We make cold-processed concentrates with great flavor profiles and all heat-sensitive compounds preserved while meeting the industrial concentration level standards. For comparison, another widely used cold concentration method is reverse osmosis which requires significantly higher pressure and longer time to concentrate juice to the same brix amount as our Natural Concentration technology can. Concentrates can be evaluated in several ways, but usually the evaluation starts with an assessment of physico-chemical parameters such as pH or viscosity and ends with a food expert panel tasting.

As a standard by the end of the process, the GCMS (Gas Chromatography-Mass Spectrometry) can be applied. Here, a small portion of the final concentrate is diluted back to its original brix level to identify and analyze potential volatile substances in the concentrate. By comparing the flavor of the original product with the concentrated juice, it’s possible to track changes in level and composition of the juice’s flavor substances. With this concentration process and technology, we give the juice industry the opportunity to produce juices of high, fresh quality bursting with flavor.