How do you use reverse osmosis in the industry?

Reverse osmosis (RO) is a widely utilized technology in various industries for water purification and wastewater treatment. It involves the use of a semi-permeable membrane to remove contaminants from water, making it suitable for a range of industrial applications. Industries rely on RO systems to achieve high levels of water purity, improve water reuse, and optimize operational efficiency. This article explores how reverse osmosis is used in the industry, highlighting the benefits and providing a detailed case study of Aquaporin's collaboration with a leading Japanese water group.

If you need more information about our reverse osmosis solutions for the industry, visit our page on reverse osmosis.

The need for reverse osmosis in the industry

Industrial operations require large quantities of high-quality water for various processes. The demand for reverse osmosis (RO) in the industry is driven by several factors. Many industrial processes, such as those in the pharmaceutical, semiconductor, and food and beverage industries, necessitate water with extremely low levels of contaminants, which reverse osmosis systems can provide. Additionally, industries face strict regulations regarding water discharge quality, and RO systems help meet these standards by effectively removing harmful substances from wastewater.

Water scarcity and rising costs compel industries to optimize water usage, and RO systems enable efficient wastewater reuse, reducing overall consumption and operational costs. The focus on environmental sustainability also makes RO systems appealing, as they help minimize wastewater discharge, lower energy consumption, and ultimately reduce greenhouse gas emissions. Finally, high-quality water is essential for maintaining industrial equipment efficiency and longevity, with RO systems preventing scale buildup and contamination, thus ensuring smooth operation and reducing maintenance costs.

General applications of reverse osmosis in the industry

Water purification:

- Pharmaceutical and biotechnology industries: RO is used to produce highly purified water necessary for drug manufacturing and laboratory processes.

- Food and beverage industry: Ensures the removal of contaminants to maintain the quality of products.

Wastewater treatment:

- Chemical plants: RO systems treat wastewater, allowing for its reuse and reducing the environmental impact.

- Manufacturing facilities: Helps in treating effluents to meet regulatory standards before discharge or reuse within the facility.

Desalination:

- Municipal water supply: RO is used to desalinate seawater, providing fresh water to areas with limited freshwater resources.

- Industrial water supply: Provides desalinated water for industrial processes that require high-quality water.

Process water treatment:

- Electronics and semiconductor industry: Ensures ultra-pure water for sensitive manufacturing processes.

- Power generation: Produces boiler feedwater and cooling water to prevent scaling and corrosion.

Case study: Aquaporin's collaboration with a Japanese water group

To demonstrate the effectiveness of the Aquaporin Inside® CLEAR membranes, Aquaporin partnered with a leading Japanese water group to reuse their wastewater at a significantly lower energy level. This collaboration highlights the potential of advanced reverse osmosis technology in achieving significant energy savings.

Background:

The Japanese manufacturer, which provides chemicals and facilities for industrial water and wastewater treatment globally, was searching for more sustainable water treatment processes. Reducing energy consumption in the reverse osmosis process was one of their key focuses.

Challenge:

The partner operates an advanced chemical research and development facility that generates a significant amount of wastewater daily. The existing reverse osmosis system was designed to recycle 50% of the wastewater for utility usage. However, the company aimed to further optimize energy consumption while still meeting the required permeate water quality.

Solution:

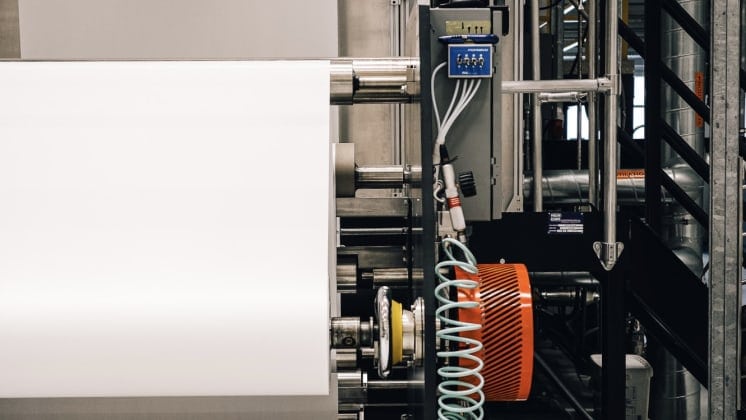

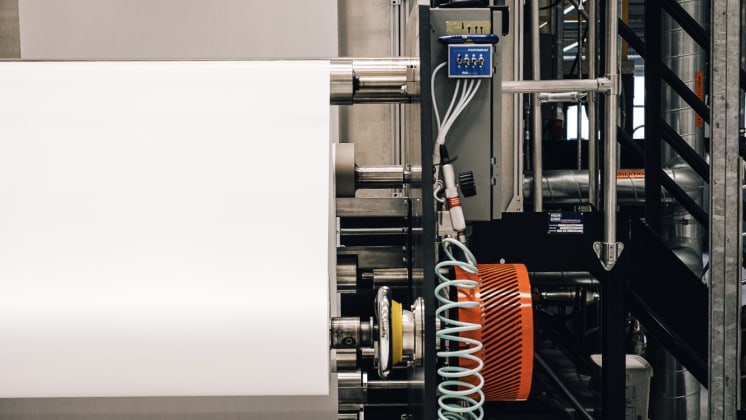

Aquaporin has developed a wide selection of Aquaporin Inside® CLEAR membranes to meet various customer demands and applications. The CLEAR Ultra membrane was selected as an ideal match for the Japanese partner's needs. This highly-permeable low-energy reverse osmosis membrane was installed in the facility.

Implementation:

The Japanese manufacturer installed 15 pieces of CLEAR Ultra 8040 elements in their 3-stage reverse osmosis system to recover 50% of the wastewater for utility usage. The test period lasted over three months, demonstrating significant advantages.

Results:

- Operating pressure reduction: The system's operating pressure was reduced by more than 60%.

- Energy savings: This reduction equaled approximately 28,000 kWh/year of electricity savings.

- Environmental impact: The energy savings resulted in the avoidance of 20 metric tons of CO2 emissions annually.

Benefits of Aquaporin’s RO technology

- Superior filtration performance: Aquaporin Inside® CLEAR membranes achieve high contaminant rejection rates, providing high-quality permeate water.

- Energy efficiency: The technology is designed to minimize energy consumption while maximizing filtration efficiency.

- Adaptability: Aquaporin's RO solutions are versatile, meeting the demands of various industrial applications with tailored membrane solutions.

You can read the full case here “CLEAR reduces water reuse energy consumption by 60%”.

Harnessing the power of reverse osmosis for industrial excellence

Reverse osmosis (RO) plays a crucial role in industrial water purification and wastewater treatment. It offers industries a reliable method for achieving high water quality, optimizing energy use, and enhancing water reuse. Aquaporin’s advanced RO technology, for instance demonstrated through our collaboration with a leading Japanese water group, showcases the potential for significant energy savings and environmental benefits. For more information about how Aquaporin’s innovative RO solutions can benefit your industrial applications, visit this page.