Why India needs to solve the water pollution issue

Environmental, health and ecosystem vitality are fast becoming key concerns in India. The industrial sector is facing pressure on several fronts to address issues of increased water consumption and water pollution.

As water is becoming an increasingly scarce resource, the continued growth of India’s economy will translate into increased demand for wastewater treatment solutions across different sectors.

In 2019, a World Resources Institute (WRI) report ranked India as the 13th most water stressed country globally. Several Indian cities, including the industrial hub Chennai, are in “extreme risk” of experiencing water shortage.

INDUSTRIAL WATER DEMAND GROWS

While agriculture is still the sector with the highest water consumption in India, industries such as textile, chemical and automotive all need massive quantities of water for their production – and the demand is growing rapidly.

At present, the industrial sector accounts for about 8–10 % of India’s total water demand, but a recent study found that industrial water demand increased at a rate of 2 % per annum, which exceeds the increased rate of agricultural and domestic water demands during the same period.

In addition to the water used for production, pollution from wastewater discharge frequently puts additional strain on water resources. As a result, factories are under increasing pressure from governments, local communities and consumers, who are demanding more sustainable production, more efficient water use and reduced wastewater discharge.

IMPORTANCE OF WATER TREATMENT

The Indian government on both the national and local level has realized the importance of better water conservation and management. In recent years, agencies such as the Pollution Control Boards and the National Green Tribunal (NGT) have imposed stringent regulation on the industrial use and reuse of water. Likewise, local authorities like the Chennai Metropolitan Water Supply and Sewerage Board have introduced numerous laws and regulations to increase incentives for reusing water, including increasing water tariffs.

This means that permissions for green field projects and brown field expansions are almost exclusively contingent on the implementation of zero liquid discharge (ZLD) or minimum liquid discharge (MLD) wastewater management.

HOW TO COMPLY WITH REGULATION

At Aquaporin, we make it possible for factory owners to comply with, and even exceed, regulations while also lowering capital and operating expenses.

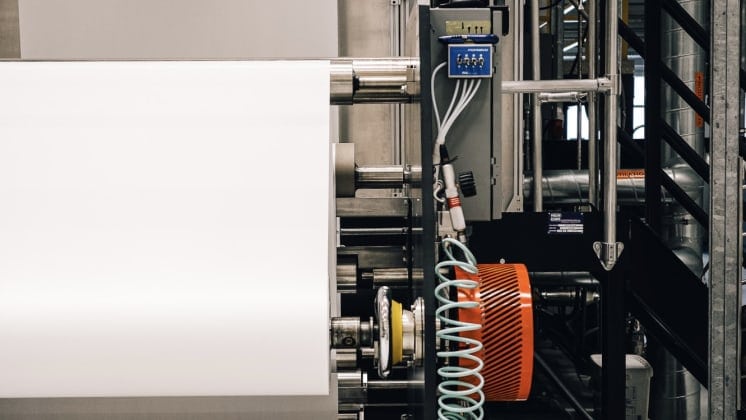

The use of membrane technology, especially Forward Osmosis membranes, can significantly improve the efficiency of industrial water treatment, improving the potential for water reuse, lower energy consumption and reduced disposal costs.

Aquaporin Inside® Forward Osmosis (FO) enables the efficient extraction of water, leaving behind challenging contaminants and reducing effluent volume. This leaves a greater quantity of purified water available for reuse while at the same time reducing the amount of energy needed to evaporate the effluent through ZLD.

The optimal solution depends on your plant and treatment goals. Wastewater streams can vary significantly from one application to another and from one industry to another. Thus, there is no one standard fit for all applications. Each case must be evaluated carefully to ensure a tailored solution for your exact needs.

LEARN MORE

Visit our industrial water page or contact us to discuss your water treatment needs and challenges. To learn more,download our e-book or go to aquaporin.com/industrial-water/